Cheapest Price Ss 304 - Welding Pipe Fitting Elbow Supplier, 90 Degree Stainless Steel Elbow – Zaihui

Cheapest Price Ss 304 - Welding Pipe Fitting Elbow Supplier, 90 Degree Stainless Steel Elbow – Zaihui Detail:

Elbows are pipe fittings that change the direction of the pipeline in the pipeline system. According to the angle, there are three most commonly used ones: 45° and 90°180°. In addition, according to engineering needs, it also includes other abnormal angle elbows such as 60°. The elbow materials include cast iron, stainless steel, alloy steel, forgeable cast iron, carbon steel, non-ferrous metals and plastics. Elbows are pipe fittings that change the direction of the pipeline in the pipeline system. According to the angle, there are three most commonly used ones: 45° and 90°180°. In addition, according to engineering needs, it also includes other abnormal angle elbows such as 60°. The elbow materials include cast iron, stainless steel, alloy steel, forgeable cast iron, carbon steel, non-ferrous metals and plastics. The ways to connect with the pipe are: direct welding (the most common way) flange connection, hot melt connection, electrofusion connection, threaded connection and socket connection, etc. According to the production process, it can be divided into: welding elbow, stamping elbow, hot pressing elbow, push elbow, casting elbow, forging elbow, clip elbow, etc. Other names: 90° elbow, right angle bend, love bend, white steel elbow, etc.

The main difference between stainless steel elbows and carbon steel elbows is the difference in material. The chemical composition contained in the elbow will keep the surface of the elbow from rust and corrosion for a long time.

According to the standard production, it can be transformed into: 90° stainless steel long radius elbow

1. According to the manufacturing standard, it can be divided into national standard, ship standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc.

2. It can be divided into pushing, pressing, forging, casting, etc. according to the production method.

90° stainless steel elbow is mainly used for connecting pipe fittings in pipeline installation, and is used for connecting pipe bends. Connect two pipes with the same or different nominal diameters to make a 90° turn.

Stainless steel elbows can also be divided into equal diameter elbows and non-equal diameter elbows. Equal diameter elbows are used to connect pipes with the same outer diameter, and non-equal diameter elbows are used to connect pipes with different outer diameters.

Stainless steel is usually made by adding a high proportion of Cr, Ni and other alloys on the basis of carbon steel, and the content ratio can reach more than 20%. Common steel grades are: 304, 304L, 321, 316, 316L, 1Cr18Ni9Ti, 0cr18ni9. The first number of steel numbers represented by numbers is Japan and the United States steel number representation method, and the last type (1Cr18Ni9Ti) is the domestic steel number representation method. Pitting corrosion of stainless steel mostly occurs in aqueous environments containing iodine, chlorine, and bromine. The reason for the pitting corrosion of stainless steel is that chloride ions are active anions, which are easily adsorbed, squeezing out oxygen atoms, and react with the cations in the passivation film to form soluble chlorides, destroy the passivation film, form small pores, and become the inducement stage of pitting corrosion. At this stage, a blocked circuit is formed, and current corrosion occurs.

9 Summary of knowledge of stainless steel elbow edit

Stainless steel elbow purpose: to connect two pipes with the same nominal diameter to make a 90-degree turn.

1. Divide carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon leaching, ppc, etc. by material.

2. According to the production method, it can be divided into pushing, pressing, forging, casting, etc.

3. According to the manufacturing standard, it can be divided into national standard, electric standard, water standard, American standard, German standard, Japanese standard, Russian standard, etc. Stainless steel is also one of the strongest materials in construction metal materials. Because stainless steel has good resistance corrosive, so it can make structural components permanently maintain the integrity of engineering design. Chromium-containing stainless steel also combines mechanical strength and high extensibility, easy to process and manufacture components, and can meet the

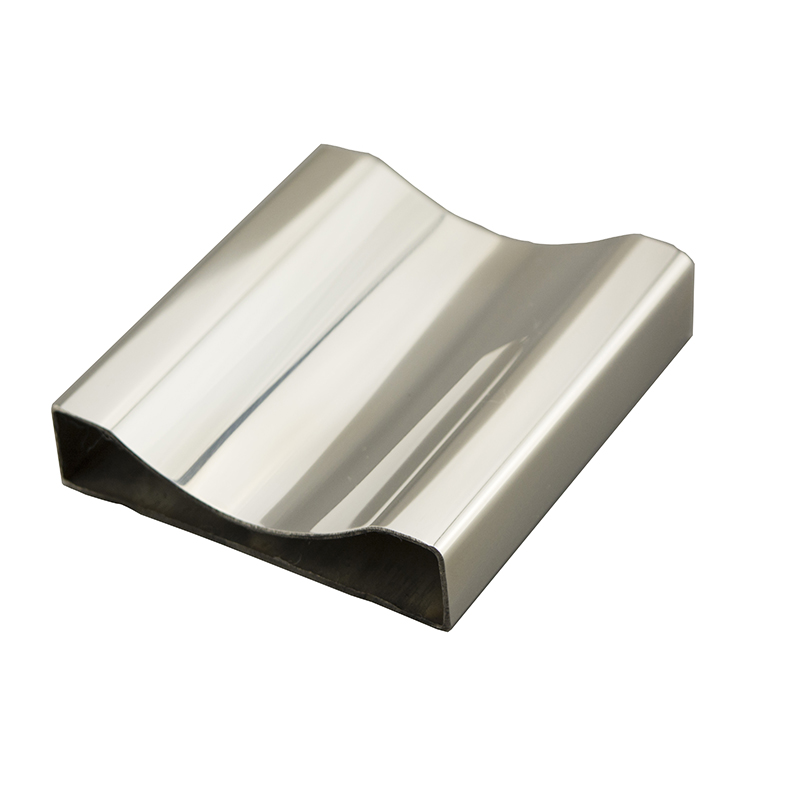

Product detail pictures:

Related Product Guide:

Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for Cheapest Price Ss 304 - Welding Pipe Fitting Elbow Supplier, 90 Degree Stainless Steel Elbow – Zaihui , The product will supply to all over the world, such as: Belize, Leicester, Brunei, Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!