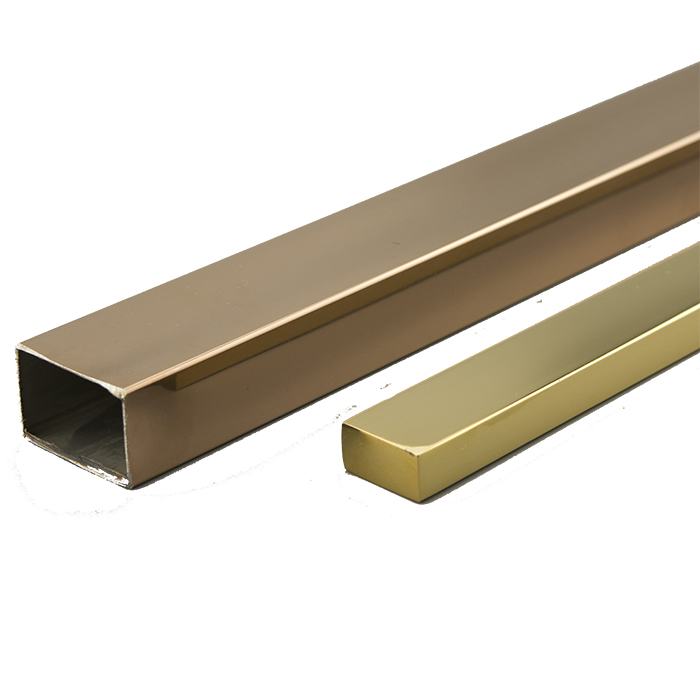

High quality stainless steel rectangular tube

There are two main types of mechanical properties testing methods, one is tensile test and the other is hardness test. The tensile test is to make a stainless steel pipe into a sample, pull the sample to break on a tensile testing machine, and then measure one or more mechanical properties, usually only the tensile strength, yield strength, elongation after fracture and are measured rate. Tensile test is the basic test method for mechanical properties of metal materials. Almost all metal materials require tensile tests as long as they have requirements for mechanical properties. Especially for those materials whose shape is not convenient for hardness testing, tensile testing has become a means of testing mechanical properties. The hardness test is to slowly press a hard indenter into the surface of the sample under specified conditions, and then test the depth or size of the indentation to determine the hardness of the material. Hardness test is a simple, rapid and easy-to-implement method in material mechanical property test. The hardness test is non-destructive, and there is an approximate conversion relationship between the material hardness value and the tensile strength value. The hardness value of the material can be converted into the tensile strength value, which has great practical significance. Since the tensile test is inconvenient to test, and the conversion from hardness to strength is convenient, more and more people only test the hardness of the material and less test its strength. Especially due to the continuous progress and innovation of hardness tester manufacturing technology, some materials that could not directly test the hardness before, such as stainless steel tubes, stainless steel plates and stainless steel strips, are now possible to directly test the hardness. Therefore, when the sanitary stainless steel pipe is tested for hardness, these details need to be done to ensure its good performance.