Hot sale Rose Stainless Steel Sheet - The company can customize the production of various styles of mirror stainless steel plate, welcome to send an email to ask me – Zaihui

Hot sale Rose Stainless Steel Sheet - The company can customize the production of various styles of mirror stainless steel plate, welcome to send an email to ask me – Zaihui Detail:

Stainless steel mirror panel, also known as mirror panel, is polished on the surface of the stainless steel panel with abrasive liquid through polishing equipment, so that the luminosity of the panel surface is as clear as a mirror. Uses: Mainly used in building decoration, elevator decoration, industrial decoration, facility decoration and other stainless steel products.

There are many mirror panels, the main products are: stainless steel coil, thick plate, medium and thick plate, ultra-thin plate, stainless steel mirror panel, decorative plate, stainless steel pattern plate; stainless steel plate surface is smooth, with high plasticity, toughness and mechanical strength, corrosion resistance of acid, alkaline gas, solution and other media.

The principle of stainless steel plate production is that the stainless steel raw material is polished on the surface of the steel plate with a polishing liquid using a polishing equipment, so that the surface of the plate is flat and the luminosity is as clear as a mirror. Stainless steel mirror panel products are widely used in building decoration, elevator decoration, industrial decoration, facility decoration and other decoration projects.

304 stainless steel plate: thickness (mm) X width (m) X length (m) X 7.93g/cm3

316 stainless steel plate: thickness (mm) X width (m) X length (m) X 7.98g/cm3

430 stainless steel plate: thickness (mm) X width (m) X length (m) X 7.70g/cm3

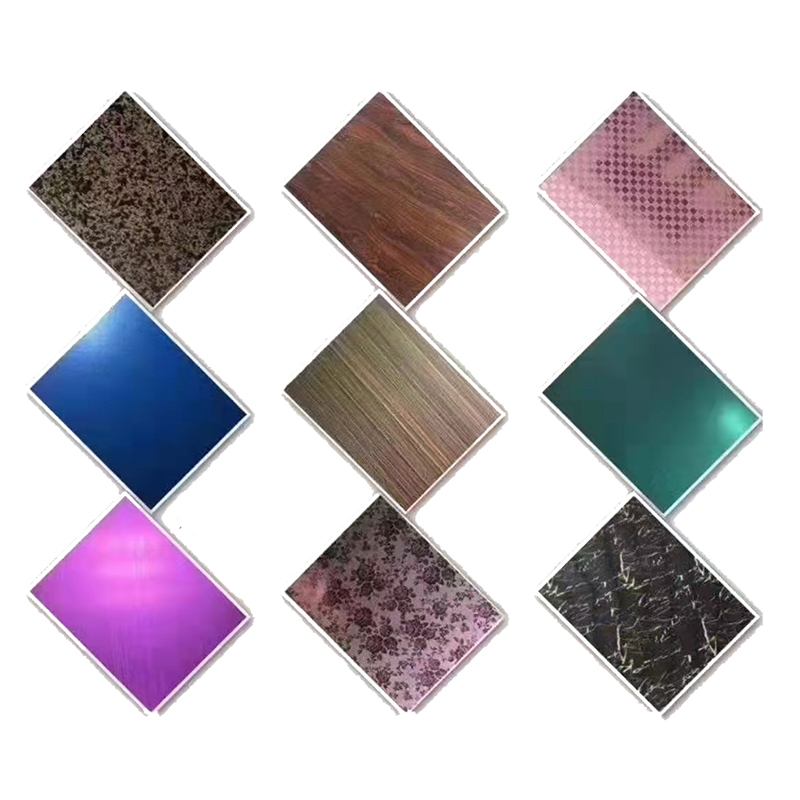

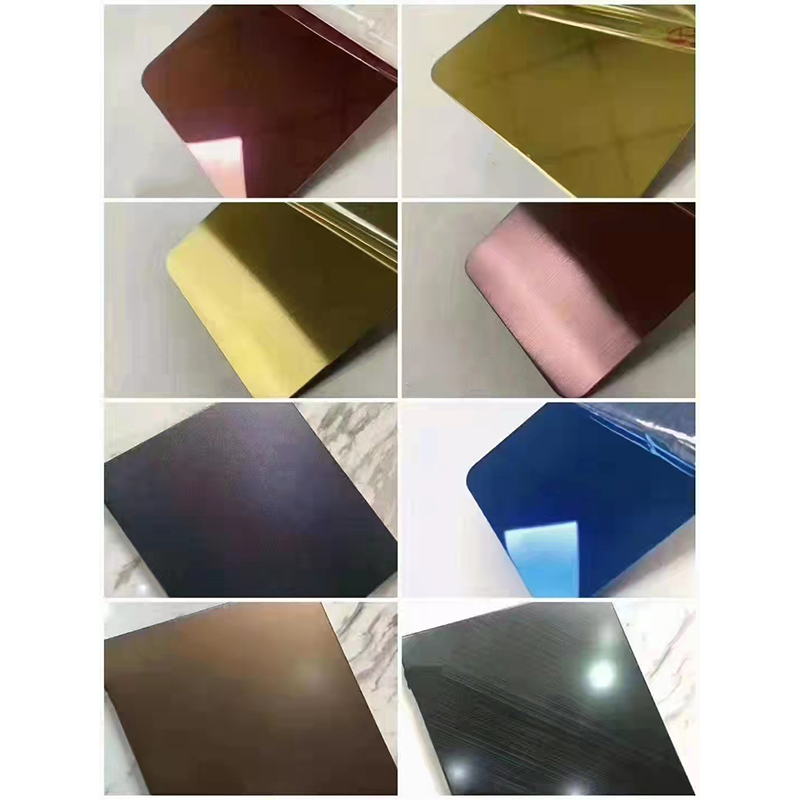

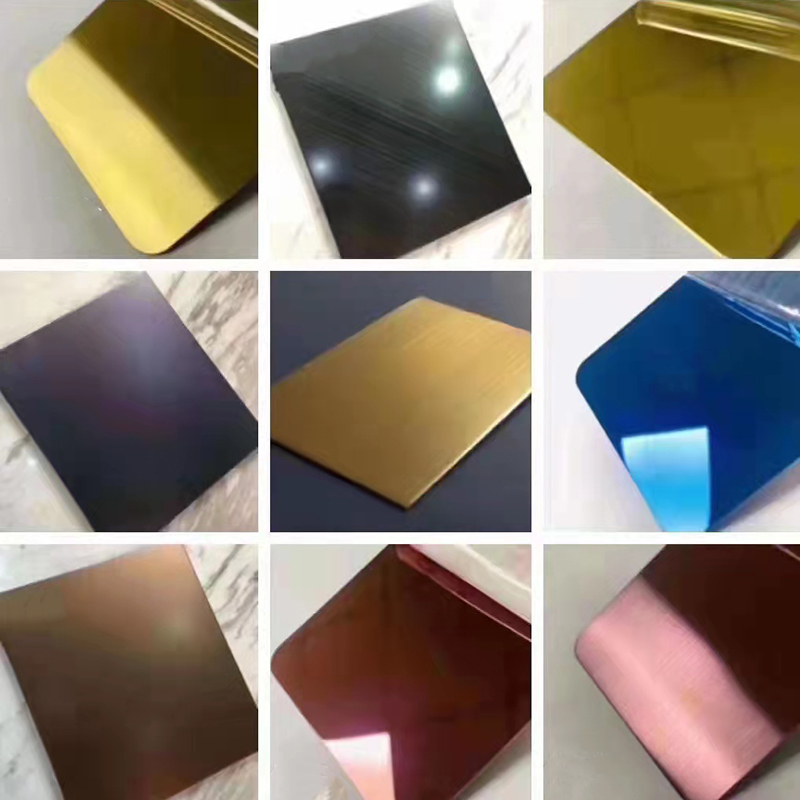

The processing and production process of stainless steel mirror panels can be divided into two methods: general grinding and fine grinding. So which of these two processing methods has a better mirror effect? And this is judged by looking at the brightness of the mirror surface, and the sand holes and grinding head flowers on the surface of the sheet must be less. Generally speaking, when the stainless steel plate is processed on a polishing machine, the slower the speed of travel, the more groups of grinding, and the effect will be very good; when the stainless steel plate is processed by polishing equipment, the first is to correct the The plate is sanded, and then the stainless steel plate is put into the grinding liquid. Among them, 8 groups of grinding heads with different thicknesses are used for grinding. The grinding process is basically the treatment of the surface of the stainless steel plate. This process has no depth at all. This step is mainly for the purpose of remove the oxide layer on the surface of the stainless steel plate. After the above process is completed, it can be washed and dried. The color stainless steel mirror panel is recolored on the basis of the stainless steel mirror panel. Now the high-grade color stainless steel mirror panel is processed by vacuum ion plating technology. Even pattern etching can be done on the mirror panel, resulting in a variety of patterns and styles of pattern etched plates.

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Hot sale Rose Stainless Steel Sheet - The company can customize the production of various styles of mirror stainless steel plate, welcome to send an email to ask me – Zaihui , The product will supply to all over the world, such as: Serbia, New Delhi, Poland, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!