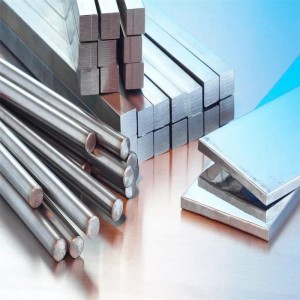

special-shaped pipe

12.7*12.7mm-400*400mm, wall thickness 0.6mm-20mm, stainless steel round pipe is generally 6*1-630*28, specifications are 4 points, 6 points, 1 inch, 1.2 inch, 1.5 inch, 2 inch, 2.5 Inch, 3 inch, 4 inch, 5 inch, 6 inch, 8 inch, 102, 108, 127, 133, 139, 159, 168, 177, 194, 219, 273, 325, 377, 426, 530, 630, etc. Stainless steel special-shaped pipes generally refer to rectangular steel pipes, triangular steel pipes, hexagonal steel pipes, stainless steel pattern pipes, U-shaped pipes, D-shaped pipes, water bends, etc.

• Shaped seamless steel pipe is a general term for seamless steel pipes with cross-sectional shapes other than round pipes.

• According to the different shape and size of the steel pipe section, it can be divided into equal-wall-thickness special-shaped seamless steel pipe, unequal-wall-thickness special-shaped seamless steel pipe, and variable-diameter special-shaped seamless steel pipe.

• Special-shaped seamless steel pipes are widely used in various structural parts, tools and mechanical parts. Compared with round pipes, special-shaped pipes generally have larger moments of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce structural weight and save steel.

• Stainless steel round pipes, stainless steel square pipes, and stainless steel rectangular pipes are conventional stainless steel pipes.

• Stainless steel special-shaped tubes are widely used in various structural parts, tools and mechanical parts. Compared with round pipes, stainless steel special-shaped pipes generally have larger moments of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce structural weight and save steel.

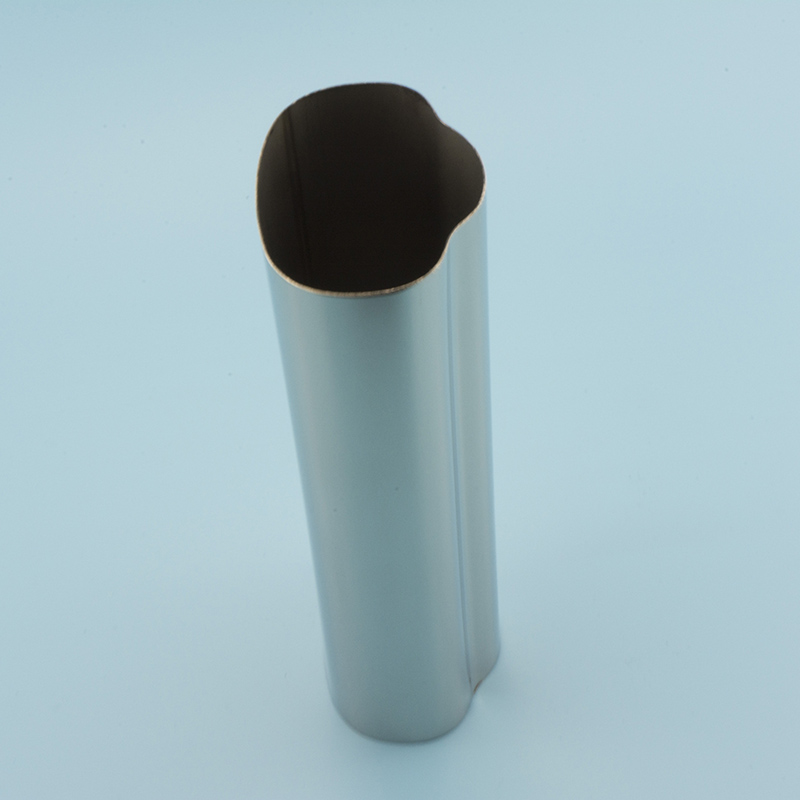

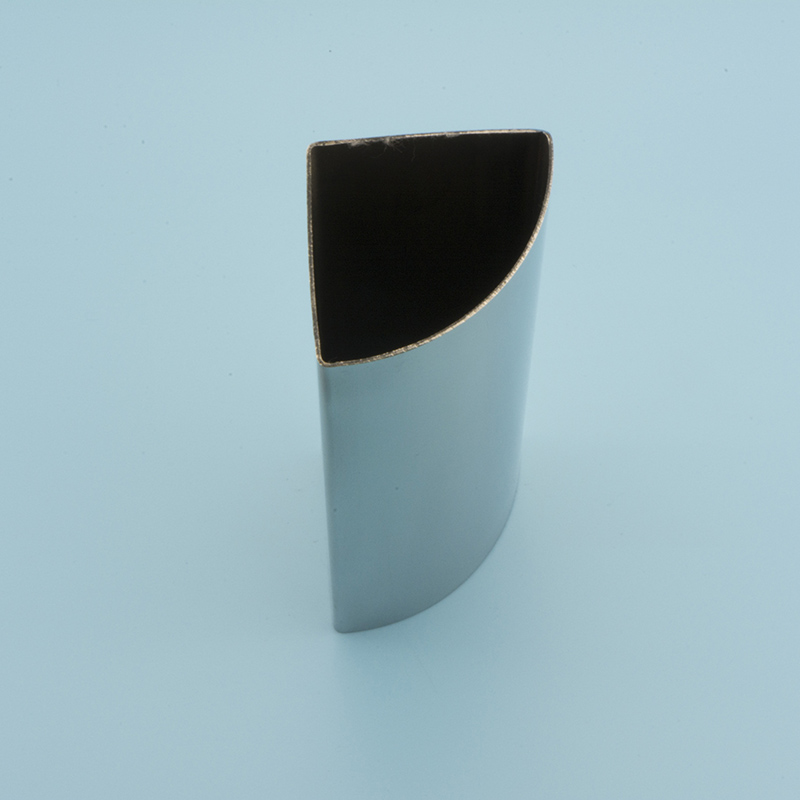

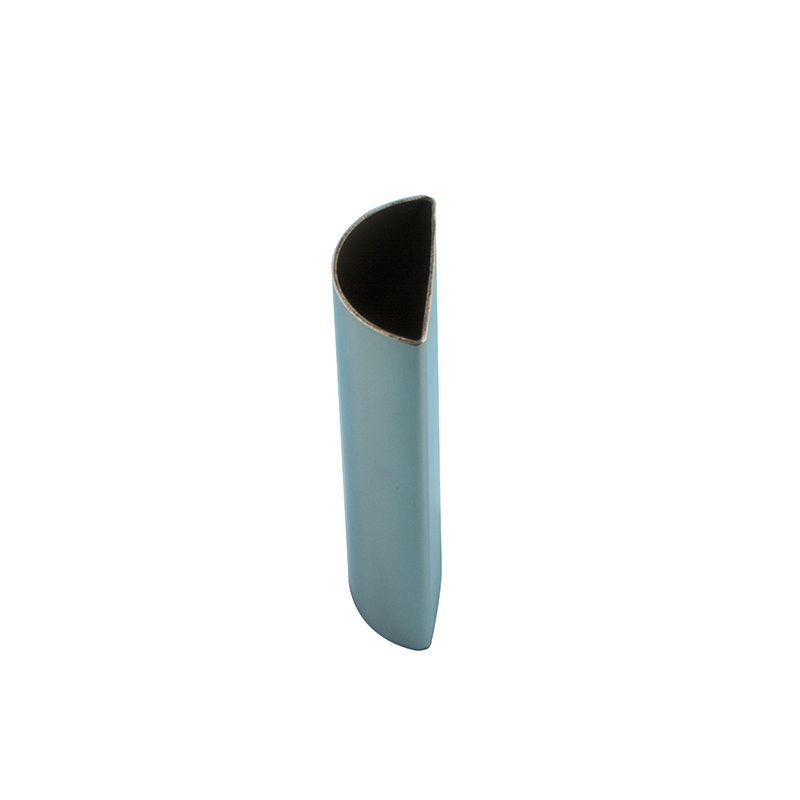

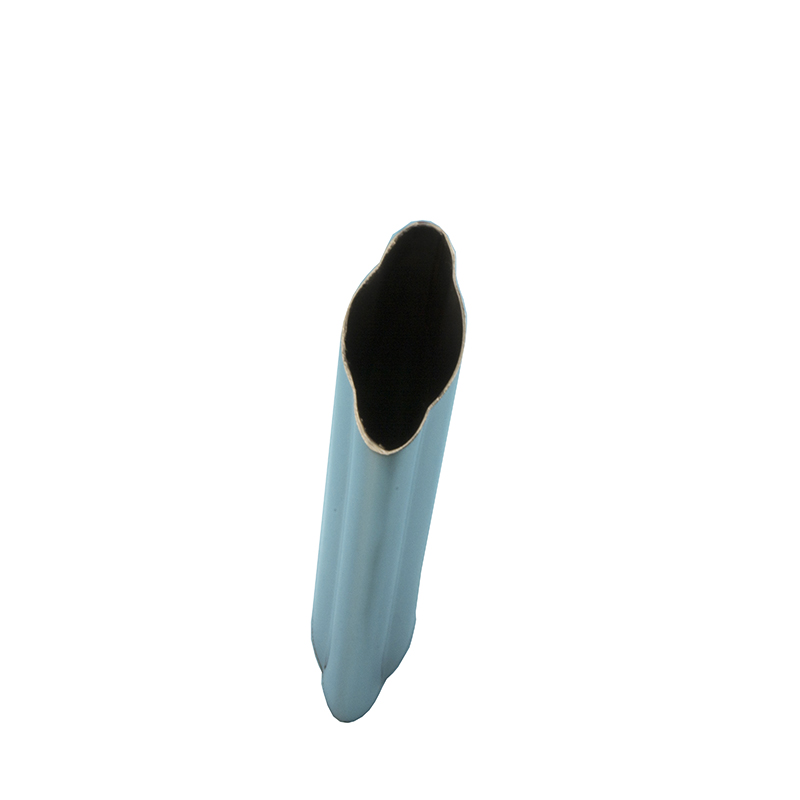

• Stainless steel special-shaped pipes are generally distinguished according to their cross-section and overall shape. They can generally be divided into: oval shaped steel pipes, triangular shaped steel pipes, hexagonal shaped steel pipes, diamond shaped steel pipes, stainless steel patterned pipes, stainless steel U-shaped steel pipes, D-shaped pipes , Stainless steel elbows, S-shaped pipe elbows, octagonal shaped steel pipes, semi-circular shaped steel rounds, unequal hexagonal shaped steel pipes, five-petal plum shaped shaped steel pipes, double convex shaped steel pipes, double concave shaped steel pipes, Melon-shaped special-shaped steel pipe, conical special-shaped steel pipe, corrugated special-shaped steel pipe, etc.

• Steel pipe shaped pipes can be divided into oval shaped steel pipes, triangular shaped steel pipes, hexagonal shaped steel pipes, diamond shaped steel pipes, octagonal shaped steel pipes, semi-circular shaped steel rounds, unequal-sided hexagonal shaped steel pipes, five-petal plum shaped shaped steel pipes , Double convex shaped steel pipe, double concave shaped steel pipe, melon seed shaped steel pipe, conical shaped steel pipe, corrugated shaped steel pipe.

• Special-shaped pipes are divided into special-shaped square pipes, rectangular shaped pipes, special-shaped welded pipes, spiral welded pipes, specifications: 20*20mm-500mm, wall thickness 0.6mm-20mm, spiral steel pipe. Spiral steel pipe specifications, 219mm-2020mm, wall thickness 5mm-20mm. Straight stitch specifications are 4 minutes, 6 minutes, 1 inch, 1.2 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 4 inch, 5 inch, 6 inch, 8 inch, 102, 108, 127, 133, 139, 159, 168, 177, 194, 219, 273, 325 and other specifications of special-shaped pipes generally refer to rectangular steel pipes.

1. Performance index analysis of special-shaped steel pipe-plasticity

"Plasticity" refers to the ability of metal materials to produce plastic deformation (permanent deformation) without being damaged under load.

2. Performance index analysis of special-shaped steel pipe-hardness

Hardness is a pointer to measure the hardness of metal materials. At present, the most commonly used method for measuring hardness in production is the indentation hardness method, which uses an indenter of a certain geometric shape to press into the surface of the metal material to be tested under a certain load, and the hardness value is determined according to the degree of indentation.

3. Performance index analysis of special-shaped steel pipe-fatigue

The strength, plasticity, and hardness discussed above are all indicators of the mechanical properties of metals under static load. In fact, many machine parts are working under cyclic loads, under this condition the parts will fatigue.

4. Performance index analysis of special-shaped steel pipe-impact toughness

The load acting on the machine at a very large speed is called impact load, and the ability of metal to resist damage under impact load is called impact toughness.

5. Performance index analysis of special-shaped steel pipe-strength

"Strength" refers to the ability of metal materials to resist damage (excessive plastic deformation or fracture) under static load. Since the load acts in the form of tension, compression, bending, shearing, etc., the strength is also divided into tensile strength, compressive strength, bending strength, and shear strength. There is often a certain relationship between various strengths, and tensile strength is generally used as the most basic strength indicator in use.

• Coat the special-shaped pipe layer with asphalt paint

• Cement mortar lining + special coating

• Coating special-shaped pipe layer with epoxy coal tar pitch

• Epoxy ceramic lining

• Aluminate cement coating and sulfate cement coating

• Coating special-shaped pipe layer with polyurethane